Circularity is not just the foundation of our business, but also a pillar of our strategy.

We design our production processes to minimize waste and landfill disposal, limit the consumption of raw materials, and prioritize the use of recycled materials.

Environmental scorecard

Our commitment to increasing the amount of residual materials sent for recovery and reuse has been confirmed by the latest results, which are monitored in the ESG Scorecard. The reduction of specific water consumption also continues, in line with our established goals.

Steel production, naturally circular

Steel is the most recycled material in the world and can be reused countless times without losing any of its intrinsic properties.

Our production cycle is a prime example of the circular economy. We produce steel from scrap metal, preventing its dispersal into the environment and reducing the consumption of natural raw materials (e.g., iron ore).

Our steel consists of 98.6% recycled material

It's not just about scrap. The vast majority of our waste and production residues are also sent for recovery and/or classified as by-products, with only a residual portion being sent to landfill.

A 360° circular approach

The first step towards a virtuous model is reducing waste generation. That's why we organize and manage our processes and plants to minimize volumes and monitor their impacts.

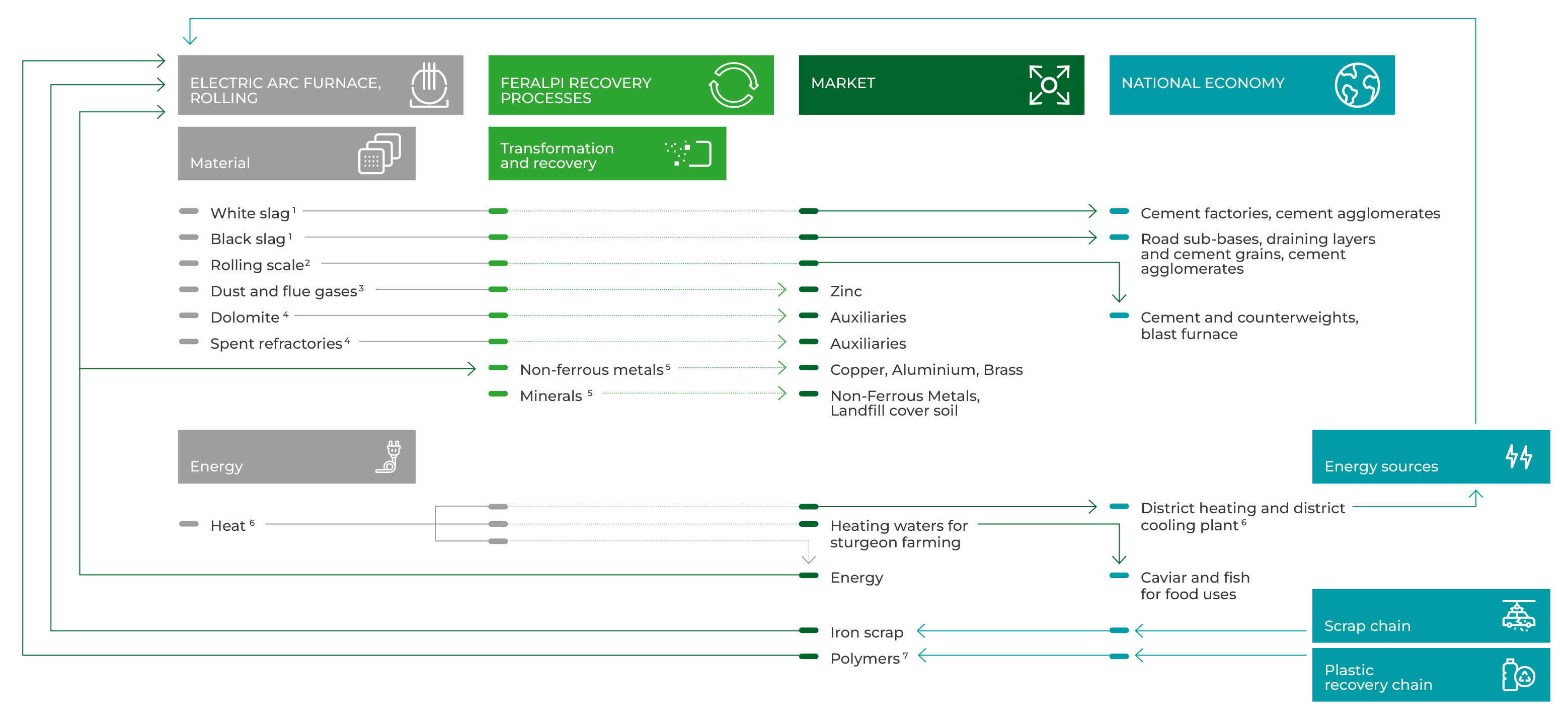

Waste valorization is part of the Feralpi Group's broader ESG strategy, which focuses on the recovery and reuse of resources. Some materials, like polymers, are fully recovered from other supply chains, while others, such as lime and refractories, are internally recycled or recovered to a lesser extent. The steel production process is constantly evolving through the adoption of increasingly advanced solutions that optimize resource use and reduce the environmental impact of our processes. Below, you can find more details on the recovery and subsequent reuse of materials within the Feralpi production process.

-

White and black slag

Slag from the smelting process can be recovered to produce building materials, such as paving and New Jersey blocks. The black slag is processed into the commercial by-product ‘Greenstone’. Feralpi is conducting further studies to develop processes for reusing white slag in building limes, plastics and within production processes.

-

Rolling scale

Rolling scale is recovered for external use. Green Iron is the by-product obtained from the rolling scale that is sold to plants for the production of ballasts and concrete.

-

Dust and fumes

The metal zinc contained in the dust resulting from flue gas removal in the smelting process is mostly recovered at external plants in replacement of natural mineral. The dust produced by the ferro alloy plant are fed directly into the production cycle, the amount of which equals that of the materials from which dust originates.

-

Dolomite and spent refractories

Spent ref ractory materials coming from the ladle are returned to the production cycle, as partial raw material substitutes. The raw material to be replaced is calcic lime and dolomite lime (“CaO cubes” and “40% CaO”) to be used as a slagging agent in the EAF (electric-arc furnace). Their reuse in the furnace does not entail any negative impact on the environment or human health.

-

Non-ferrous metals and minerals

The residual fraction produced by the scrap selection plant is sent to external plants for the recovery through mechanical sorting of non-ferrous metals (such as aluminium, brass and copper)

-

Heat

Heat is recovered from the cooling water systems of the Feralpi Siderurgica and the Riesa steel mills, preventing it from being released into the atmosphere.

-

Polymers

The polymers - sourced only from plastic packaging from separate waste collection - are subjected to sophisticated sorting and classification processes at modern, qualified industrial plants and then to technological treatment for recycling. Such processes transform treated plastic materials into new “circular raw materials” that comply with regulations and quality standards, becoming important resources for various industrial applications.

Since 2023, calculations have also been made for the aggregates produced by the Group, which have the following values:

- GREEN STONE ≥ 96.6 %

- GREEN LIME ≥ 100 %

- GREEN IRON ≥ 100 %

Water resources

Water management is essential for the steel industry, especially for cooling plants. The Feralpi Group adopts rigorous monitoring and reporting standards for the responsible use of water resources, reducing withdrawal and consumption while promoting reuse in industrial processes. In Italy, we ensure water is treated and discharged in compliance with Legislative Decree 152/06, thanks to dedicated plants and controls by accredited bodies. In Germany, we operate under specific permits for discharging wastewater into the public network.

Our goal is twofold: to decrease water withdrawal by optimizing the operation of our cooling circuits, and to ensure the thorough purification of water released from our plants.

To reduce consumption we use rainwater

Rainwater is collected on all impermeable surfaces and treated in purification plants. Some of the water is then used in the industrial process. Among the many initiatives implemented over the years, construction began in 2024 at the Riesa site on a tank to collect rainwater from the roofs of the new Building B rolling mill. This 350 m³ tank will enable the recovery and reintroduction of rainwater into the cooling and process circuit, saving approximately 6,000 m³ of drinking water from the public network each year. It is scheduled to become operational in 2025.