The history of the Feralpi Group started with the action of a woman - Giulia Tolettini, who was Carlo Pasini’s Mother and took over the running of the family forge in Odolo around 1940.

From that point onwards the business continued to grow, until 1968 when Carlo Pasini decided, along with other associates, to build the new steel production premises in Lonato (Brescia).

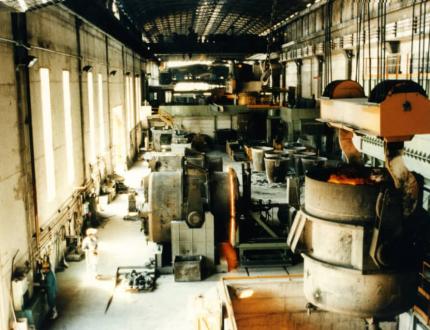

Steel casting began in 1969 after the inauguration of the plant, which covered an area of 500 m2 and had a production rate of 25 tonnes of steel/hour. The mill was equipped with a 130,000V electricity substation, a cooling water system with a well 100 metres deep, and an elevated tank 30 metres in height with a capacity of 150,000 litres. Technological innovation therefore commenced in Feralpi's initial years, and in 1970 the mill was integrated downstream with a rolling mill for medium to large cross-section rebar. The plant was high-tech with a high level of automation. A second furnace came into operation the following year, bringing the year's production to 74,530 tonnes of medium to large cross-section rebar. Even logistics became a strategic asset, and the site was equipped with a railway siding with an internal track of 2 km.

In 1972 additional equipment came on stream, with a continuous casting process to produce billets. In the same year Feralpi shareholders and local partners took part in the construction of a new steel mill in Calvisano (BS), with a 50-tonne furnace for producing billets for use in rolling processes. In 1974 another 30-tonne furnace and a new 3-line continuous casting process was set up for the production of billets. Steel mill production reached 203,750 tonnes and rolling mill production reached 188,450 tonnes. A focus on the environment resulted in the installation of an off-gas purification plant, and a third furnace also commenced operation, which also had a purification plant attached. In 1975 the plant was equipped with a shredder upstream, to crush scrap cars. The aim was to improve the quality of the scrap on which the efficiency of the entire production cycle depended.

Ongoing research into high-performance products took shape, and in 1988 the company was one of the first in Italy to obtain the patent for the production of rebar using the Tempcore process, which guarantees the high quality of the finished product.

The continual improvement of production processes took another step forward in 1990, with the installation of a shearing press for cutting scrap, to optimise the scrap iron supply and processing phase.

A vision that had always been based on internationalisation became even more concrete. The Feralpi Group was quick to pick up on market opportunities in Europe after the collapse of the Soviet regime. Commercial and production operations then commenced in Hungary (Ozd and Budapest), and the Czech Republic (Kralupy).

The key milestone of the internationalisation process occurred in 1992 with the establishment of ESF Elbe-Stahlwerke Feralpi in Riesa in Saxony, in what had been East Germany. With this investment the Feralpi Group took over and relaunched a historic steel production site with centuries-old tradition (it was established in 1843), and became one of Europe's major steel manufacturers, with a considerable presence in the leading two manufacturing markets - Italy and Germany.

In 1997 the three furnaces in Italy were completely replaced with one of a higher capacity, and with one five-line continuous casting process. Feralpi was also one of the first in the sector to install an off-gas collection and emission reduction system. The production of reinforcing steel in coils and wire rod commenced in 2001, and a new recoiling plant was installed.

In 1999 Feralpi entered Romania by acquiring 50% of Ductil Steel Sa, specialising in the production of wire rod, rebar and down-stream processed products.

In the meantime, continuous casting commenced in Germany in 1994 after a major industrial revamp, and the rolling mill became operational the following year. From that point onwards, 500,000 tonnes of steel for reinforced concrete would be produced in Riesa, where cold working also started in 1996 to extend the product range.

The investments never stopped - in 2001 at Feralpi Siderurgica the production of reinforcing steel in coils and wire rod commenced, and a new recoiling plant was installed.

2004 was the year that Feralpi, always one step ahead, voluntarily published its first Sustainability Report for the three-year period 2002-2004. In the spirit of transparency, it was drawn up with the awareness that economic performance is not the only measure of value created.

Also in 2004 the Group prepared for a new structure - present in five European countries with several operational companies, Feralpi restructured the organisation by establishing Feralpi Holding.

The development of the business continued. While remaining loyal to its core steelmaking business, in 2007 diversification into the environmental, energy, fishing and finance sectors commenced.

The Feralpi Group opened the doors of the Lonato site and celebrated its 40th anniversary with the community, sharing this important moment with those who participated in the company's history with passion and pride, be it directly or indirectly.

In the same year, Elbe-Stahlwerke Feralpi GmbH reached a production level of one million tonnes with 600 employees.

After extending its scope of action in Europe, the Feralpi Group also targeted the verticalisation of the business. In 2009 the company DE.FI.M. in Alzate Brianza (CO) was taken over and renamed Nuova Defim SpA, manufacturing welded wire mesh for construction and industrial use, and metal wire gratings and fencing for civil and industrial applications. This first step preceded numerous others.

In 2009, the technology to control atmospheric pollution was recognised by the Federal Ministry for the Environment in Germany as the best technology available.

Technical innovation and the willingness to invest continued. A new, highly innovative smelting furnace was installed at the headquarters in Lonato del Garda, capable of optimising use by operators in complete safety. Feralpi earmarked 10 million euro for the plant, which was at the forefront in Europe due to its cutting-edge safety characteristics and process control.

The first sustainability report was published in 2011 for the Riesa facility and the two wire processing plants in Kalrupy (Czech Republic) and Csepel (Hungary).

In 2012 Feralpi pushed verticalisation further by taking over the company Orsogril, through Nuova Defim. This historic Como-based company produced steel gratings for use in construction and architecture, and the takeover created the only company in Europe providing the market with metal grating and wire solutions.

Keen to capitalise on business opportunities outside of Italy, in 2013 Feralpi Algérie was established with its headquarters based in Orano, to best serve the North African market.

In the same year, Feralpi received the 2013 Saxony Environmental Award for its new steam and energy generation system (producing energy using waste heat from the electric furnace) at the innovative ESF plant in Riesa.

Feralpi Siderurgica entered the higher added value steel sector by acquiring a 50% share of Caleotto SpA (formerly Lucchini), a major rolling mill for the production of quality wire rod for numerous conventional and innovative applications.

With a longstanding steelmaking tradition in this business, Caleotto brought high-profile expertise and specialism to the Group.

In 2015, acquiring a 48% share in Presider and Metallurgica Piemontese Lavorazioni (MPL), specialising in the pre-processing and on-site installation of rebar and steel beams respectively, demonstrated the Group's strong commitment to verticalising the organisation.

2015 was the year of the global EXPO event in Milan. By supporting the Orgoglio Brescia association, which created and produced the Tree of Life design for the event, the Feralpi Group used its steel to contribute to the event’s iconic international symbol. Even the main EXPO thoroughfares, the Cardo and Decumanus roads, the Palazzo Italia building, the Brazil pavilion and the hanging gardens carried the hallmark of the Group's steel, with products and services by Presider, MPL and Nuova Defim Orsogril.

In 2016 the Feralpi Group acquired a new production facility in Nave (Brescia), establishing Feralpi Profilati Nave, specialising in the production of rolled angle sections, U-sections and T-sections.

Feralpi took another step forward by taking over the entire stake of MPL and Presider, which in turn expanded with Presider Armatures in Paris.

The Feralpi Group celebrated its 50th anniversary with gratitude by opening up its doors to its local community. In one day only, almost 9000 visitors attended the event, with more than 2000 of them visiting fully operational production departments.

This was the year that Feralpi restyled the company logo, to express the identity of an international steelmaking Group that made diversification and verticalisation its focus for development, nurturing it by continually improving technology and safety standards.

In the same year, the colours of the Lonato site were updated to make it fit more harmoniously into its surroundings.

The system to recover heat from the Lonato del Garda steel plant was connected and enabled to supply the district heating network for the area and community, leading to environmental, economic and safety benefits.

The Feralpi Group acquired 100% control of Caleotto SpA production facility based in Lecco, making the Feralpi Group more vertical and integrated in the special steels market. In 2020 Feralpi also defined a new industrial setup for the facility in Nave (BS), to convert it to cold-working operations for steels destined for construction and large developments with Presider.

The Feralpi Group published its first voluntary non-financial report (NFR), consistent with its commitment to transparency and reporting practices.

Defim Orsogril – Feralpi Group company – acquires the Spanish firm Saexpa, specialized in solutions for the logistics sector, specifically in racking systems for vertical warehouses and storage solutions. This is a rapidly growing field, driven by increasing investments in modern distribution and e-commerce.

In the same year, Feralpi Power On is founded. It is the Feralpi Group company dedicated to the development and operation of power generation plants, primarily from renewable energy sources.

With the 2023 financial year, Feralpi prepares its first Integrated Report, aimed at combining the reporting of financial performance with the disclosure of Environmental, Social, and Governance (ESG) information.

Presider, part of the Feralpi Group since 2015, strengthens its presence by inaugurating its new branch in Nave (Brescia) and expanding its network in Northern Italy. This integration includes the sites in Borgaro Torinese (Turin), Pomezia (Rome), and Saint-Soupplets (Paris), where it operates as Presider Armatures to serve the French large-scale construction market.

Feralpi officially becomes one of the first companies in the European steel sector to receive approval from the international Science Based Targets initiative (SBTi) for its 2030 goals to reduce CO₂ and other greenhouse gas emissions.

Feralpi has incorporated an ESG strategy into its development plan, aligned with international sustainability goals and climate change mitigation efforts. In particular, on the environmental front, to contribute to the targets set by the Paris Agreement (COP21), the company defined, submitted, and obtained SBTi approval for its interim targets, fully in line with global agreements.

On May 15, 2025, FERALPI STAHL inaugurated its new “Rolling Mill B” in Riesa. The plant, which operates with zero direct emissions (Scope 1), marks a major technological breakthrough: it is the first in Germany to enable continuous rolling through billet welding and is equipped with a zero-emission inductive furnace system.

With this investment, FERALPI STAHL becomes the first company in Germany to produce Spooler coils and the first in the world to produce Spooler coils weighing up to 8 tons.

FERGreen is the full range of low-impact steel products for next-generation construction. It represents Feralpi Group’s concrete response to the growing demand for sustainable solutions in the building sector.

FERGreen is part of the Group’s ESG (Environmental, Social, Governance) strategy, which places decarbonization at the heart of its industrial plan. The range includes all construction steels produced by Feralpi, both in Italy and Germany.